Circumferentially Axiperiodic Diaphragm: Axi section

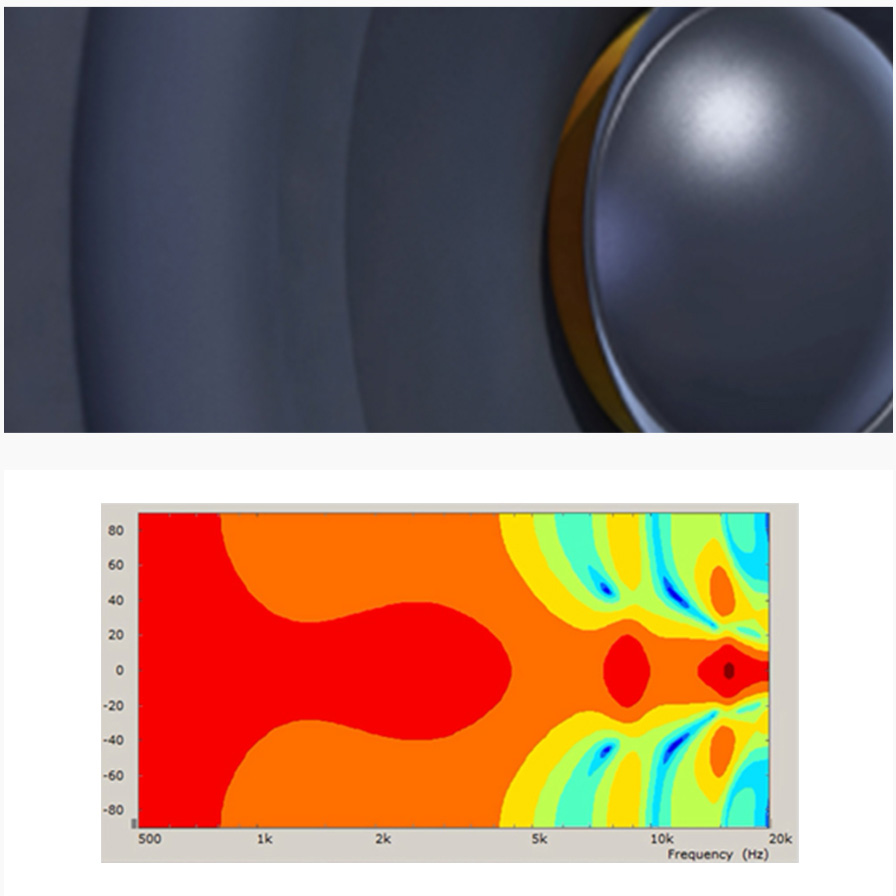

Central to the ground-breaking performance of the Axi2050 is a heavily sculpted, circumferentially AxiPeriodic annular titanium diaphragm. Its unique periodically symmetrical curved elements allow both the large diameter necessary to reproduce a wide frequency band and the low mass required for higher efficiency, while also reducing the number of vibration modes in the critical listening band for a very low distortion performance. The geometry allows the shape of the mechanical modes to be tailored so they do not couple with the acoustic modes, so there are no large resonance peaks.

Maximum Modal Suppression

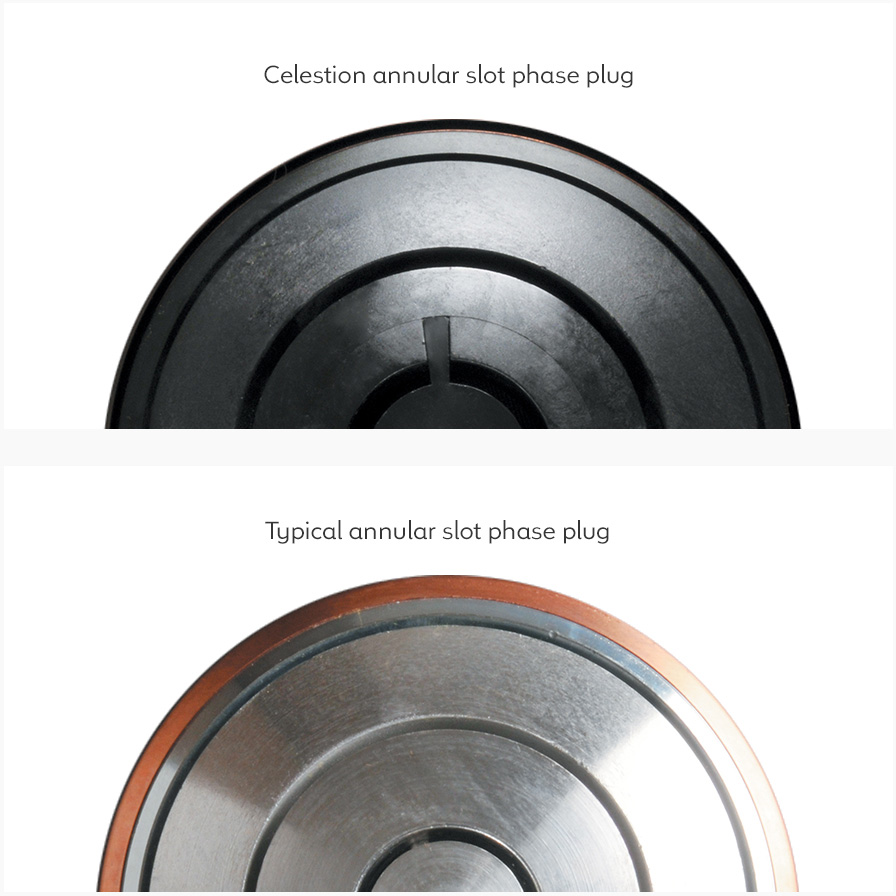

A number of models in Celestion’s range of compression drivers make use of the ground-breaking MMS™ (Maximum Modal Suppression) phase plug design. Applying advanced mathematical analysis to the motion of a curved diaphragm, Celestion’s Group Research team developed a new method for calculating the width and position of the slots used in a phase plug. Building on long-established technology, this patented design significantly reduces the occurrence of unwanted resonances in the cavity between the diaphragm and the phase plug itself. The result is greater modal suppression and reduced air non-linearity. The benefit is a better time domain response and much lower distortion than the existing industry standard.

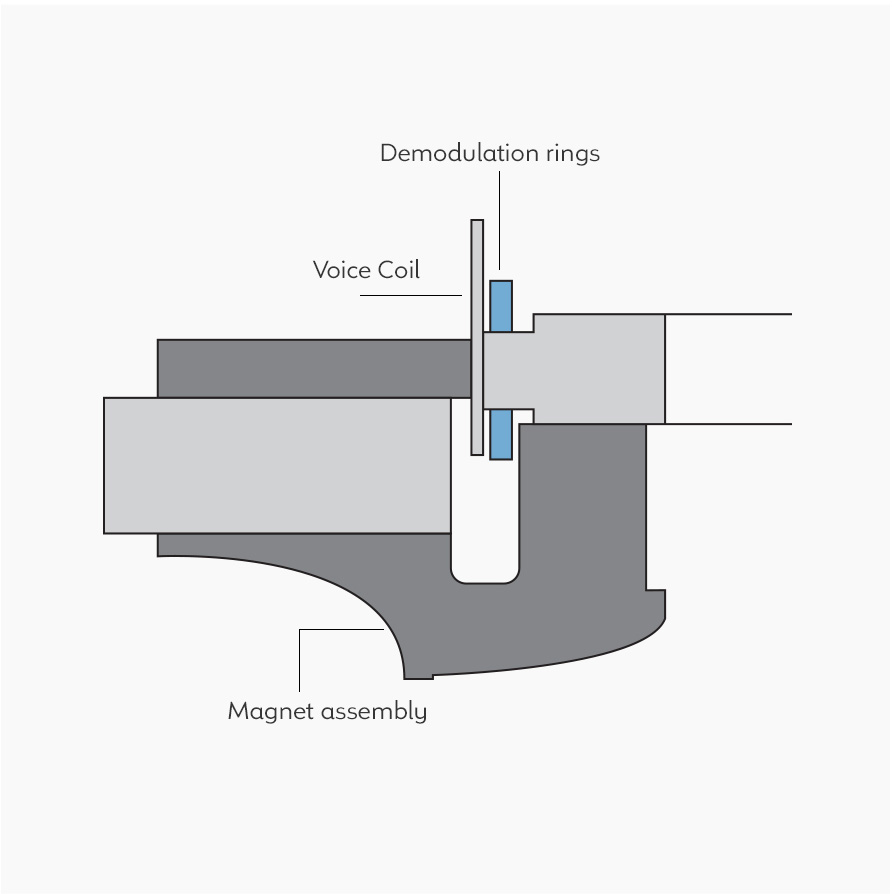

Demodulation Rings

Many LF speakers in the Celestion range as well as the FTX coaxial drivers feature either one or two demodulation rings. Commonly made from aluminium, these conductors are an intrinsic part of the magnet assembly employed to substantially reduce both the harmonic and intermodulation distortion associated with voice coil displacement. They also act to make the variation of system inductances more linear as input current varies, which noticeably improves distortion performance.

A copper sleeve added to the pole piece of midrange and compression drivers has a similar effect, reducing inductive rise for improved HF performance.

Deep Drawn Diaphragm

Working together with the MMS phase plug the “deep-drawn” titanium diaphragm has been manufactured with a taller dome shape to improve stiffness. The deep-drawn diaphragm exhibits first modal break up around 15 kHz, compared to a typical compression driver diaphragm which starts to break up in the 8-10 kHz range. The higher threshold frequency of the diaphragm avoids the break-up within the critical mid-range listening band that is associated with lower profile diaphragms, meaning greater clarity of performance with much less distortion.

Sound Castles

Celestion’s highly successful Sound Castle™ clamping system features on many of our most successful compression drivers. It was developed to ensure an even clamping pressure on the diaphragm surround, reducing distortion while simplifying maintenance in the field. They also allow the full internal volume of the rear cover to act as a loading chamber for the diaphragm, resulting in superior lower mid-band response. The recently introduced, next-generation “soft clamping” Sound Castle assembly reduces diaphragm stress to a greater degree which cuts distortion still further and ensures an even more reliable performance.

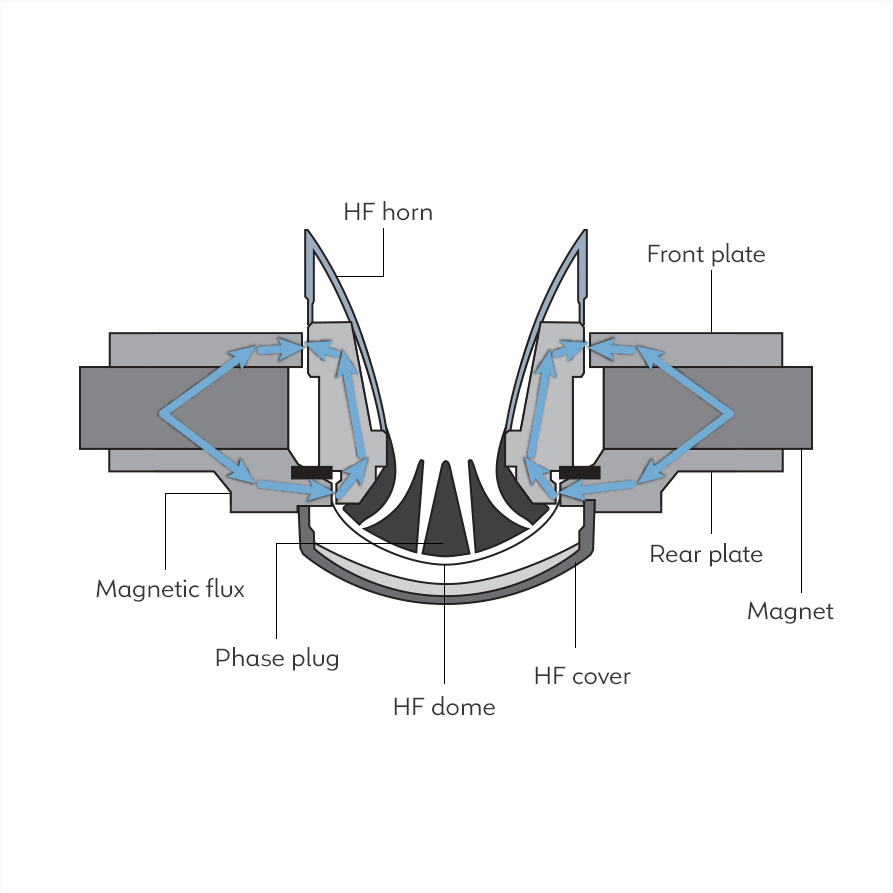

Common Magnet Motor

The FTX coaxial drivers feature fully combined Low and High Frequency components powered by a Common Magnet Motor Assembly, where the same ferrite magnet is used to drive both elements. This precision-designed magnet assembly has been optimised using finite element analysis techniques so that it distributes magnetic flux to both LF and HF voice coil gaps in the most efficient way possible, to extract optimum performance from the system.

This design brings the voice coils and hence the acoustic centres of the two components closer together compared to those of a conventional coaxial driver. It delivers further improvements in signal coherence and time alignment for more natural sounding audio reproduction. The use of a single magnet assembly also means lighter weight and a profile that is more compact than conventional coaxial designs.

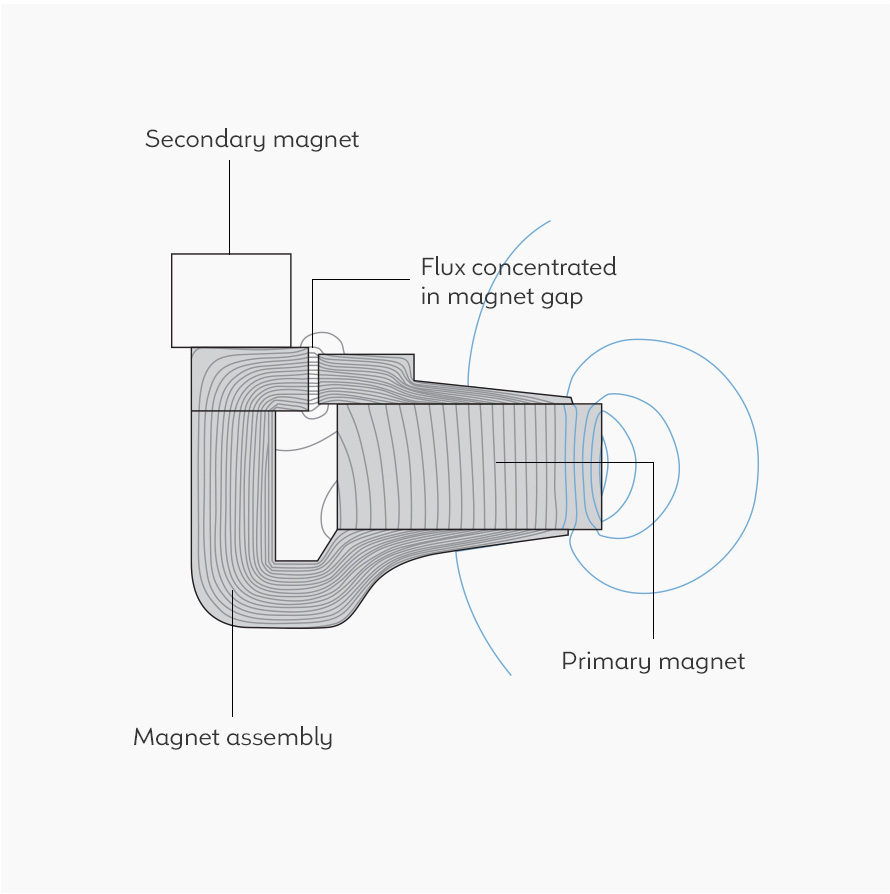

Dual Magnet Motor

A secondary magnet is employed within the assembly to increase the overall motor efficiency. This results in a measurable increase in Bl, enabling higher sensitivity models to be produced where the application demands, without needing to significantly increase overall magnet assembly size and weight.

Integrated HF Waveguide

The specialised dustcap with integrated waveguide featured on the AN series compact array drivers deliver greater dispersion to higher frequencies than many equivalent compact drivers. This is one of the features of the AN drivers that facilitates closer coupling when using multiple drivers, meaning these drivers are particularly suited to use in controlled wavefront (beam steering) column arrays.

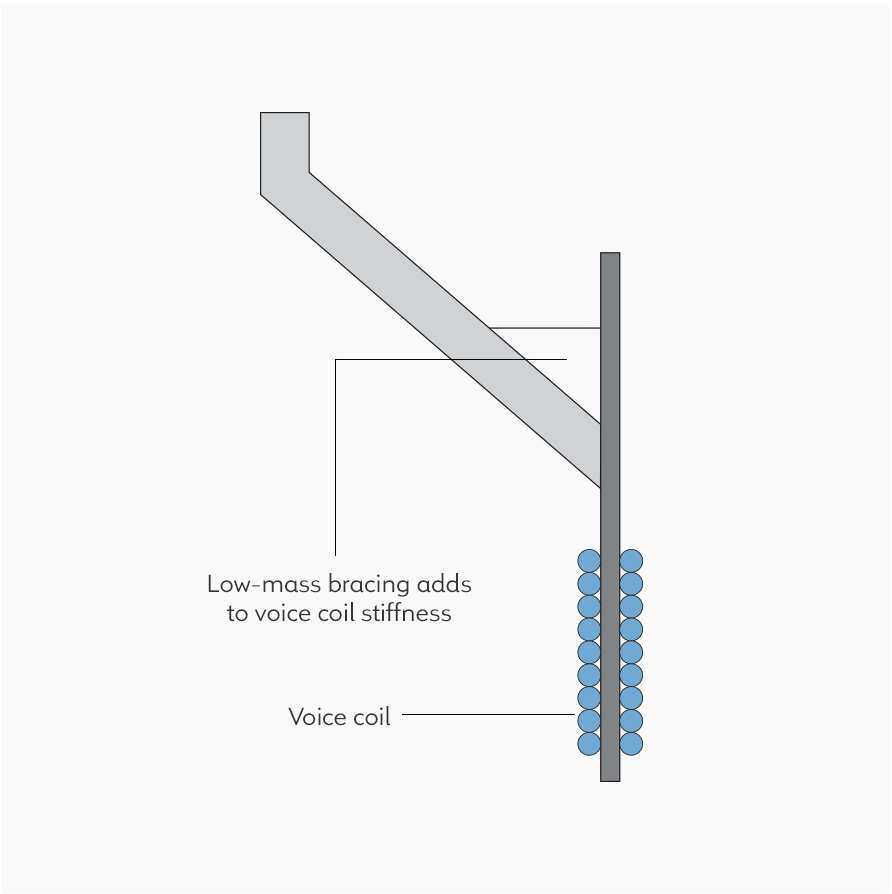

Low Mass Coil Reinforcement

In general for LF speakers there’s a compromise made between high output sensitivity and long Xmax. Longer throw drivers tend to have lower sensitivity. Higher sensitivity drivers tend to have a shorter throw. Improving the stiffness of the voice coil without adding to the moving mass by any meaningful amount, enables the overall loudspeaker sensitivity to be increased, while maintaining a longer Xmax than would otherwise be possible.

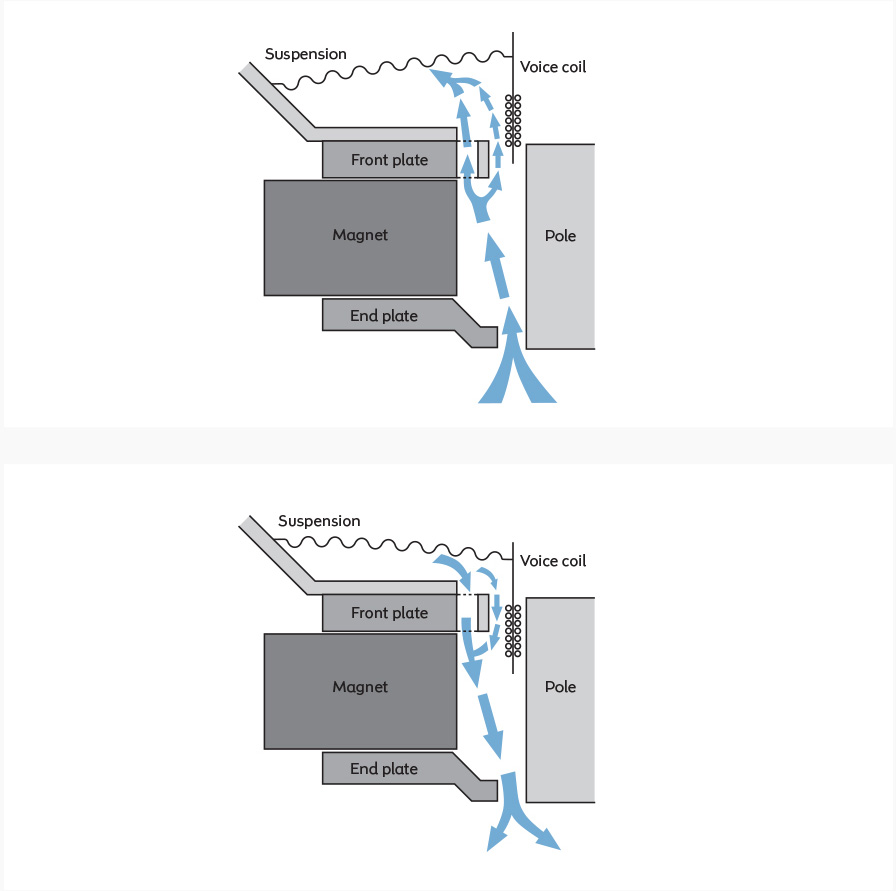

Balanced Airflow Venting

Balanced Airflow Venting (BAV) builds on Celestion’s principles of dynamic heat dispersion for enhanced cooling. Strategically sized and positioned airflow channels are located in the magnet structure to produce a balanced flow around the voice coil, as the air is pumped by the suspension and dust cap. This rapidly takes the heat away from the magnet assembly, actively cooling the system and counteracting the effects of thermal compression.

Optimised Suspension Systems

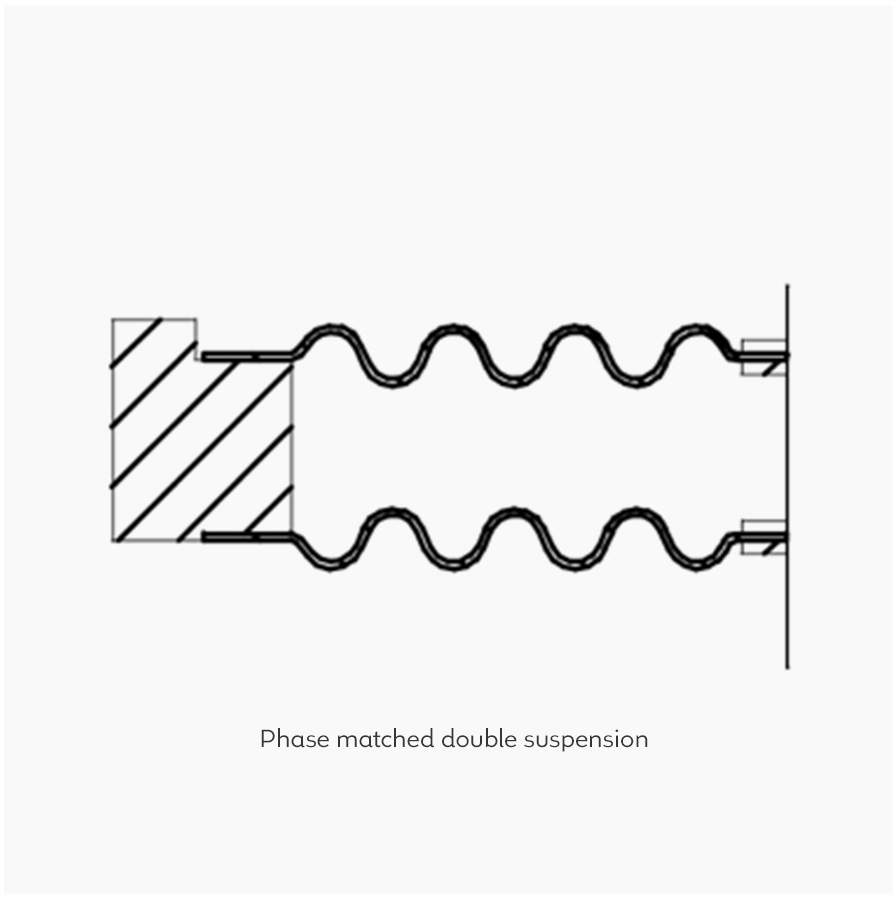

The inherent shape of the voice coil suspension has a direct effect on the linear excursion of the cone. This can sometimes be a cause of non-linearity in driver performance.

Phase-matching double suspension systems, placing the two individual suspensions in opposing polarities, enables the removal of the non-linearity. The result is a much more balanced and symmetrical cone motion, hence lower distortion.

Inverted Dust Cap

For horn-loaded midrange applications, the inverted dust cap enables OEM designers to position a phase plug much closer into the cone, minimising distortion by significantly reducing the possibility of destructive interference.

Application-Specific Cone Surrounds

For low excursion designs, a environmentally robust, high temperature foam surround provides a good match to the impedance of the cone, ensuring sound waves are not reflected back along the cone surface. It also maintains flexibility over a wide temperature range.

Elastomer surrounds deliver a lower resonance for enhanced low frequency performance, with greater stability at extremes of excursion for very long throw applications.

High Temperature Voice Coils

Celestion uses a range of voice coil winding techniques to achieve a number of performance advantages:

• Greater motor symmetry: even for large diameter, large voice coil devices

• More effective cooling, preventing sensitivity loss through thermal compression

• Maximised motor strength.

Inside/Outside coils are wound on both the inside and outside of the former. This is conducive to greater Bl symmetry and by effectively doubling the potential heat-dissipation surface area greatly improves cooling.

Multi-layer voice coils have the coil wire wound in multiple layers around the same side of the voice coil former bobbin. This effectively increases the length of wire within the magnet gap to maximise the speaker’s motor strength. The result is a higher Bl from a compact magnet assembly.