Ten Key Features

That add up to a new standard in LF driver performance

The Ten2 development program revisited every detail of driver design, developing and testing a series of incremental improvements that combine to redefine standards of performance and durability in professional low frequency loudspeakers.

See detailed specifications for TSQ2460, TSQ2145 and TSQ1845.

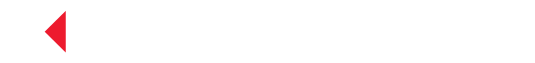

Precision Tuned Venting

Precision Tuned Venting (PTV) harnesses the cooling effects of constant airflow in a set of precisely dimensioned vents, enabling cooling around the coil and magnet assembly to be significantly improved – by up to 80C compared to conventional designs.

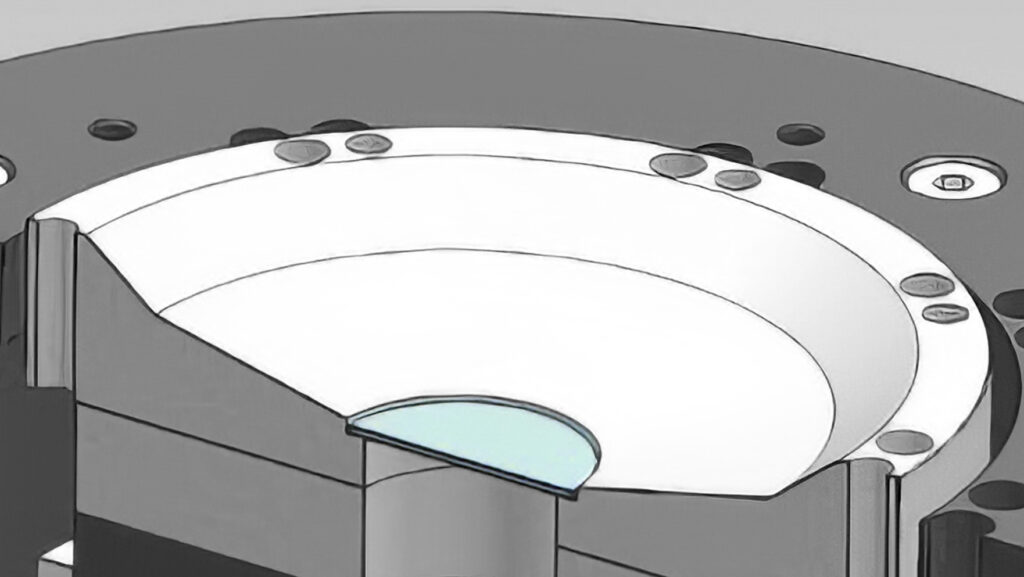

Reduced Power Compression

Highly efficient PTV cooling delivers additional reduction in power compression (loss of driver efficiency), as well as lower thermal stress on the voice coil, leading to improved performance, endurance and longevity.

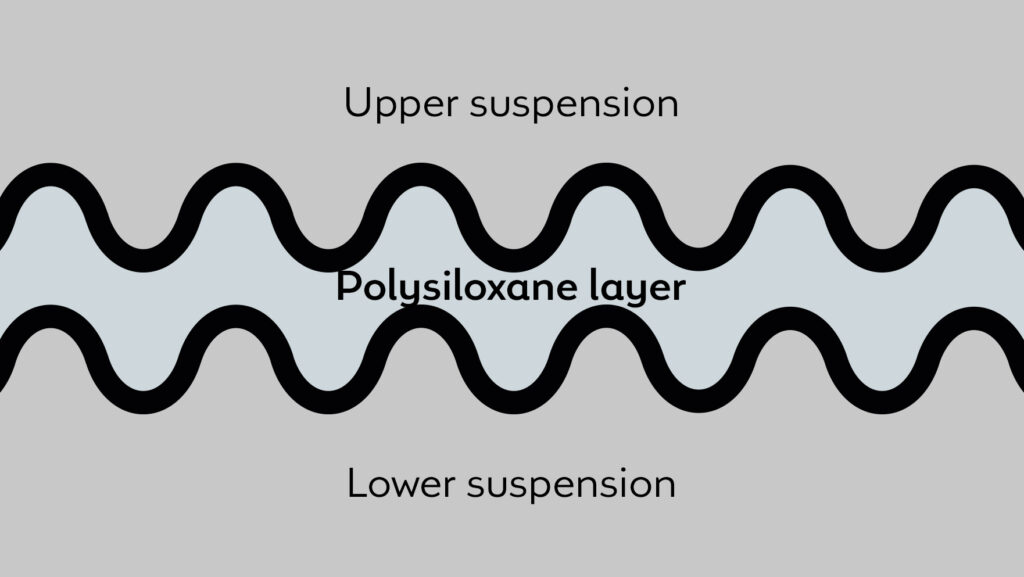

Polysiloxane Laminated Dual Suspension

Polysiloxane (a silicone polymer) is sandwiched between two resin- impregnated layers which enables the laminated suspension to be worked much harder without losing stiffness, giving better coil control, making DC shift less likely and increasing speaker longevity.

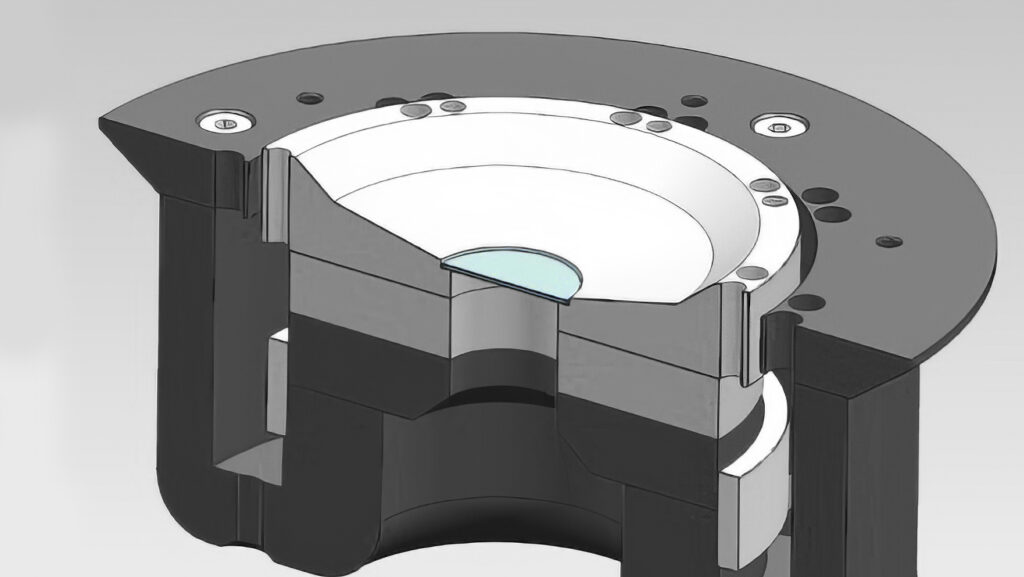

Reconfigured Magnet Assembly For Greater Excursion

A re-configured magnet assembly allows much greater cone excursion before damage occurs (Xmech) and best-in-class Xprotection (the distance the coil and cone move, measured to the point where both Bl and Cms have both reduced to 30% of their resting value).

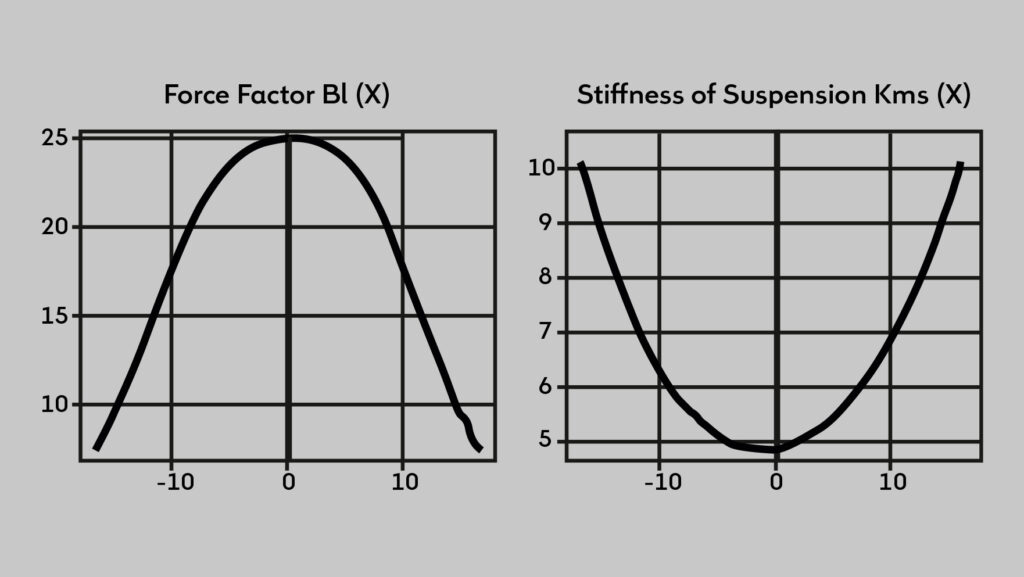

Convergent Motor Strength & Mechanical Compliance

Electrical motor strength Bl and mechanical compliance Cms reach their defined Xprotection limit at practically the same point: achieving a low distortion performance even during high excursion.

Custom Voice Coil Structure

Celestion winds its own voice coils using proprietary adhesion and voice coil structure solutions to maximise product lifespan and performance longevity.

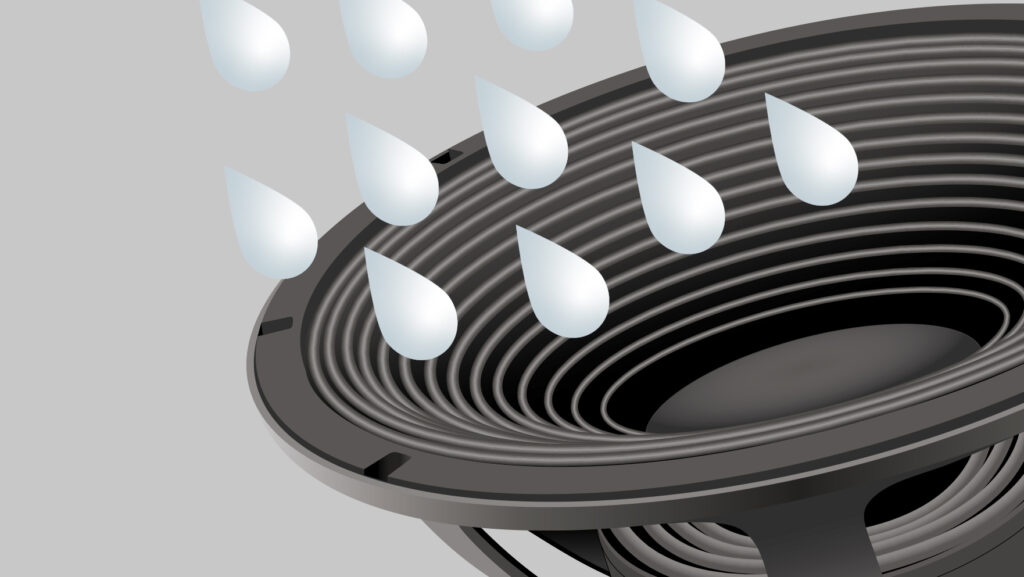

Enhanced Moisture Protection

A water-based solvent is applied to one or both sides of the loudspeaker’s cone (depending on speaker model and desired application). This significantly improves the driver’s ability to resist direct exposure to water and higher levels of humidity, and also improves product durability.

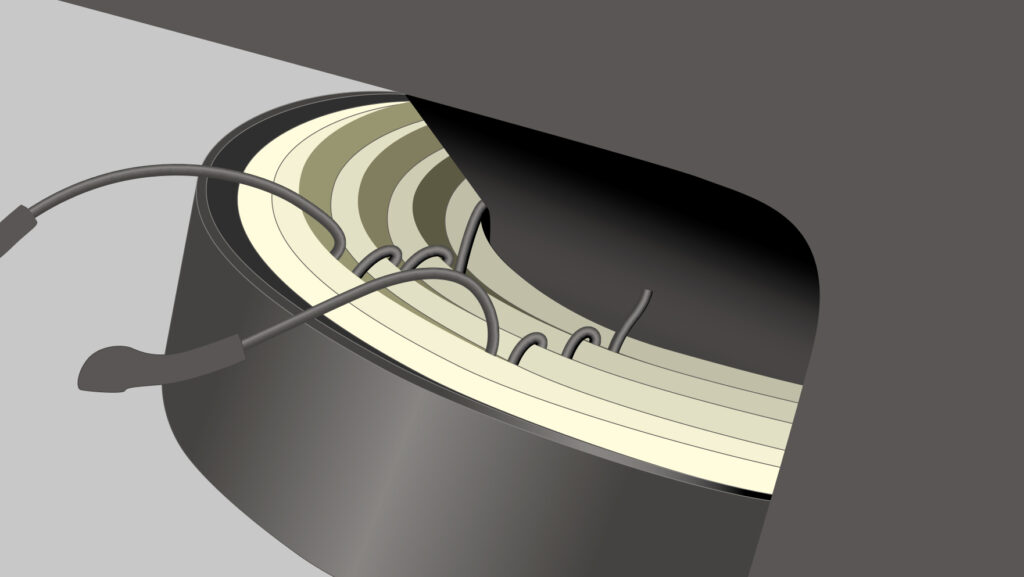

Laser-Cauterized Lead Out Wire Holes

Weaving lead out wires into the suspension through laser cut holes reduces ‘whipping’ and lessens the fatigue on wires and joints caused by high power and cone excursion.

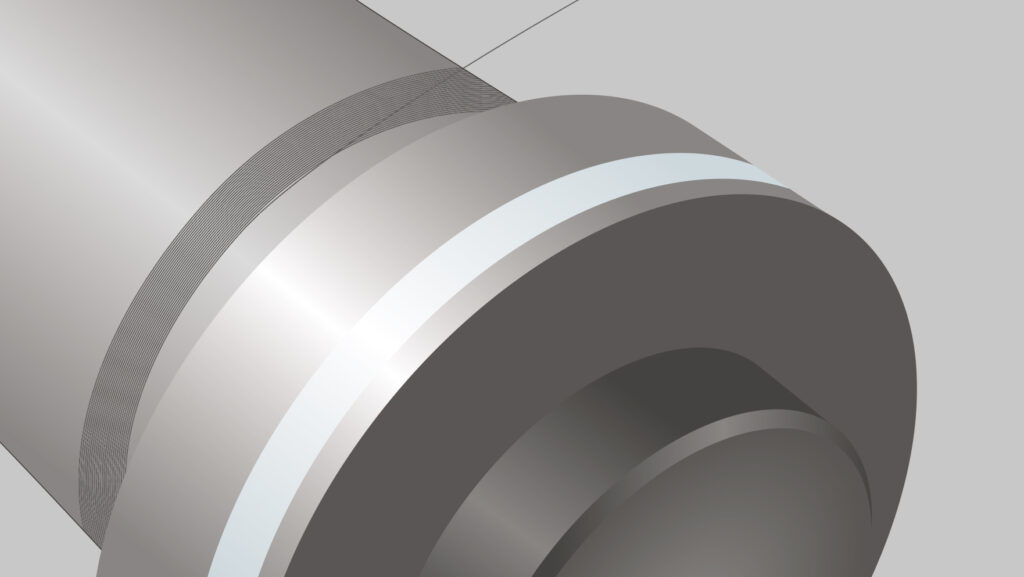

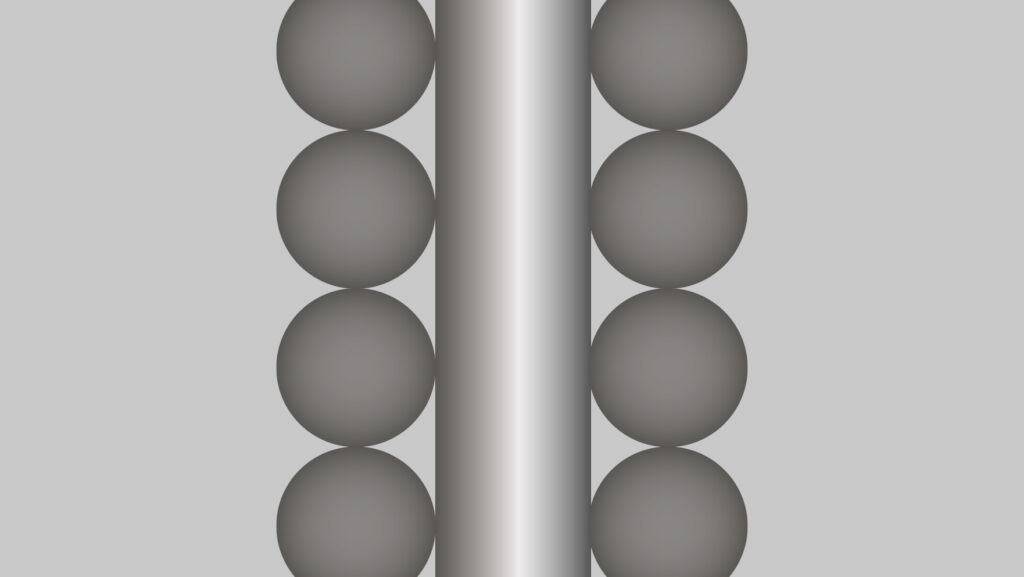

Multi-layer Inside/Outside Coil Windings

Celestion’s voice coils are wound inside/outside in multiple layers, to maximise cooling potential with the greatest amount of surface area exposed to free air. This further contributes to the reduction of both power compression and thermal stress.

Precision built in the UK

TSQ drivers are built on the newly-commissioned, robotically-assisted production line at Celestion’s UK-based loudspeaker research and manufacturing facility, and rigorously tested in line with an exacting list of performance criteria.